The HVACR Advisors WICF load calculator is a fully-featured web app which allows the user to determine an accurate design heat load for a walk-in cooler or freezer so that refrigeration equipment can be appropriate sized. This web app evaluates heat loads from the following four sources:

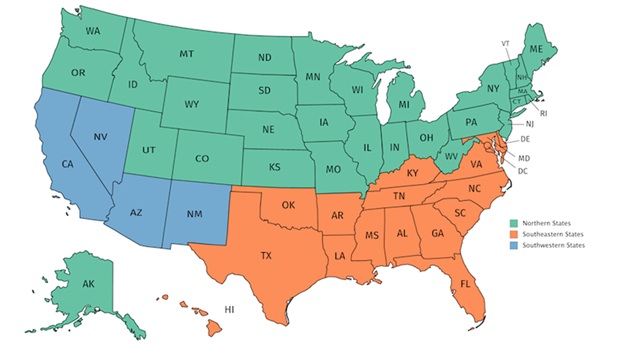

More often than not, the information needed to determine these loads is not available. This WICF quick load calculator provides an estimation of the heat load using only the walk-in box dimensions and desired box temperature. This calculator also considers whether the walk-in is located indoors or outdoors, and the region in the U.S. where it is located. This calculator uses the regions established by the U.S. Department of Energy (DOE) for SEER efficiency standards in 2015. The map is shown below.

If the user clicks the Use Geolocation? checkbox, the app will locate the user using HTML5 geolocation and automatically select the region.

The following assumptions are used to determine the average load. Many of these assumptions are also used by other quick load charts.

Transmission Load:

Infiltration Load:

An air change method is used. The average air changes per day is correlated to the volume of the walk-in as follows:

| Volume, ft³ | Cooler, > 32°F | Freezer, ≤ 32°F |

| 200 | 44 | 33.5 |

| 300 | 34.5 | 26.2 |

| 400 | 29.5 | 22.5 |

| 500 | 26 | 20 |

| 1000 | 17.5 | 13.5 |

| 1500 | 14 | 11 |

| 2000 | 12 | 9.3 |

| 3000 | 9.5 | 7.4 |

| 4000 | 8.2 | 6.3 |

| 5000 | 7.2 | 5.6 |

| 10,000 | 4.9 | 3.8 |

| 15,000 | 3.9 | 3 |

Please note the air changes for the indoor walk-in is assumed to be twice that of the walk-in located outdoors, and will result in the infiltration load for the indoor walk-in to be much greater. The reason for this assumption is an outdoor walk-in is generally used more for storage and subject to less door openings. In addition, for indoor walk-ins, an additional input for the number of glass display doors is provided. These are doors on the walls of the walk-in which allow customers to access product without the need to enter the walk-in.

If an outdoor walk-in is to be actively used like an indoor walk-in, consider having the app calculate a quick load for an indoor walk-in instead.

Product Load:

Internal Load:

A safety factor of 10 percent is applied to the load. In addition, the load is adjusted for an 18 hour/day equipment run time.

The heavy load calculation assumes the product load is 3 times greater than the average load and infiltration load is 50 percent greater than average load. All other assumptions remain the same.

Both average and heavy load calculations are displayed.

The Detail page provides a breakdown of the quick load calculations. This can be useful for applications where information is available to determine some of the loads. For example, transmission and product loads can be determined but infiltration and internal loads cannot.

| Back |